Optical detectors "BQ" of moving yarns

1.Application

BQ sensors are designed to detect presence of ayarn at draw-twist machines. They can be advantageously used evenon other types of machines and appliances where ballooning or traversing yarns.The moving yarn is monitored by an infra red beam. There is no contact with theyarn and clearances are such that anybuilt up of dirt, fly, and spin finish on the detector are minimal. Reliabledetection is possible for a wide range of neutral or synthetic yarns as well asblends and filaments such as nylon, glass and carbon fibre. Sensitivity is notaffected by colour, material, spin finish or conductivity.

2.Description

BQ sensor is a compact unit containing scanningelements, amplifier, signal evaluation, and output switch circuit. The systemresponds to signals produced by the yarn motion. A compensation circuitcorrects for even extreme build up of dirt and fly, to ensure 100% accurate andreliable detection of breaks.

A part of the sensor is a connection cableended according to a customer's requests. In the sensor's body, there are twoholes for fastening the sensor and two control lamp diodes. The red controllamp diode HL1 (on the left side when looking from the operating area) signalsthe absence of the oscillating motion inoperating area. The control lamp diodeHL2 on the right, serves to signal states of superior appliance according toneeds of user.

3. Technical Data

Operating and storage conditions:

Accurate and failure-free operation is guaranteed in case that the following conditions are observed:

- Operating environment temperature 0 – 45 °C

- Air pressure 85 – 106 kPa

- Relative humidity is max. 95% when absolute humidity of environment should not exceed 40 g/m3

- Minimal distance from a light source under operation (fluorescent tube 40W) is 1 metre.

- Sensor should be stored in dry, clean, and ventilated rooms without aggressive gasses; at the temperature from – 20 °C to +55 °C and at relative humidity from 40% to 85%

Operation parameters

| Version | BQxx 12V | BQxx 24V |

| Supply Voltage | 10 - 15V | 21 - 27V |

| Current Consumption | max. 45mA | max. 45mA |

| Operating Area | 40/50 mm | 40/50 mm |

| Yarn Count [mm] | min. 0,1 mm | min. 0,1 mm |

| Ballooning/Traversing Frequency | 2 - 200 Hz * | 2 - 200 Hz * |

| Reaction Time Delay | 0,7 s * | 0,7 s * |

| Class of protection | IP 30 | IP 30 |

Note.: * Changes possible after agreement with producer

Sensor versions according to the output types:

BQx6 – the output element is made by an open collector of transistor (24V/100mA), common GND. At presence of moving yarn, the transistor is connected at GND; HL1 – is not lighting . HL2 - signalling is or is possible at the input IN.

BQx6P - the output element is made by an open emitter of transistor (24V/100mA), common + 24. At presence of moving yarn, the transistor is connected at + 24V; HL1 – is not lighting . HL2 - signalling is or is possible at the input IN .

BQx7 – the output element is made by a relays contact (DC 24V/0.5A, AC 120V/0.5A R ). In your order, it is necessary to state which contacts should be using , i. e.: closing contact, break contact, or change-over contact. HL2 signalling can be common to HL1 or at the input IN.

BQx8 – the output element is made by a tyristor anode (24V/20mA). The tyristor closes (to GND) at the moment in which yarn stops moving, and at the same time the HL1 light starts to flash. HL2 signalling is at the input IN.

BQx8N - the output is the same as at the BQx8. By connecting the input IN to GND, it is possible to shorten the reaction time, whereat HL2 flashes at the rhythm of the moving yarn.

Light Signalling: HL1 flashing red light – signals a yarn break, the moving yarn in the operating area is not present. H2 input IN – might be used to indicate sensor powering, respectively to signal state of place outwards of the machine.

Cable Connection: supply cable of the length L is ended with a connector according to the given specification

4. Installation instruction

The sensor is fastened by two pins M4 so that the controlled moving yarn intersects the infra red beam. The connection cable should be fastened not to be subjected to tension and bending to avoid a rapture. The optical elements can be covered with dust during the operation. Thus it is convenient to wipe them with a dry, soft tissue or clean them using alcohol.

5. Repairs

The sensor does not need any set up under the operation. Any possible defects are recommended to be sorted out by changing sensors and sending the defective sensors back to producer for repair. In case of any check on the device, consumer looses warranty rights.

6. Order Specification

BQ xxx xx V ( x, l )

...1.2...3......4..5...

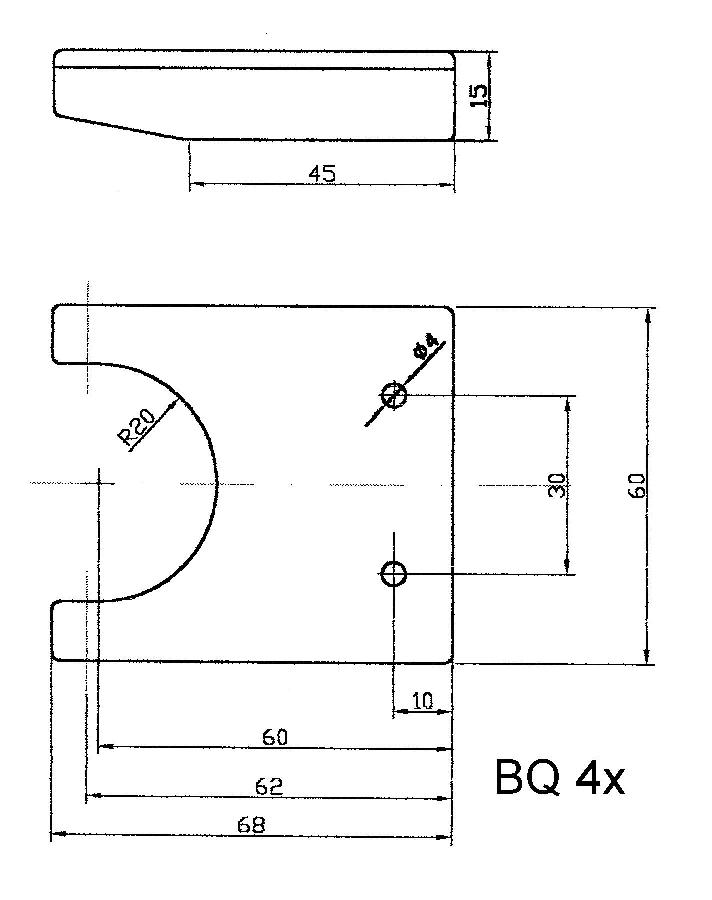

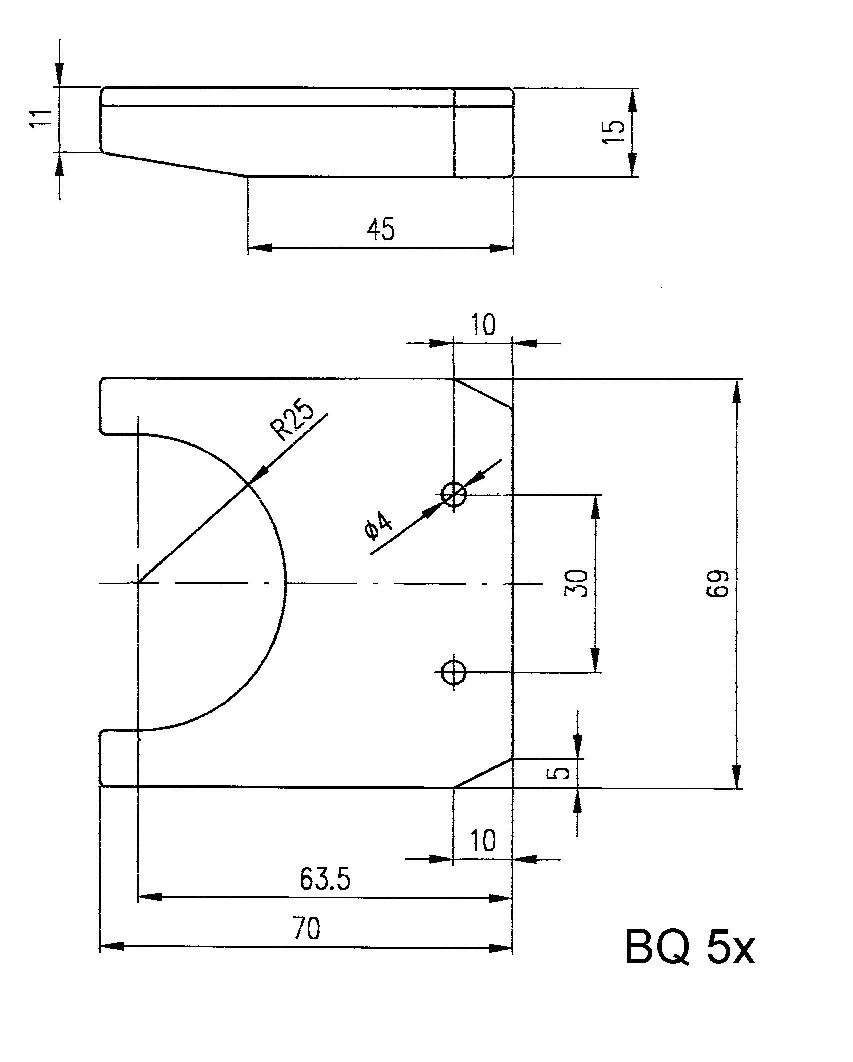

1 - Sensor operating area spacing (4,5) .

2 - Type of sensor according to the output version (6, 6P, 7, 8, 8N)

3 - Supply voltage (12V, 24V)

4 - Cable endings (P-point, K-connector SVS5, X-connector XLR, F- fast-ON

5 - Cable length in centimetres

Performing of the input IN (colour and implementation of control lamp diode HL2) after an agreement with a producer.

BQ47 Sensors are available with screwed connecting block without a cable.

Delivery date: up to the amount of 200 pcs ... 1month, for orders of higher delivery than that, it is necessary to make an agreement with the producer.

Contact address:

Ing. Zdeněk Stříbrný

Sportovní 268, Želešice 664 43

Czech Republic

Tel.: +420 547 217 606

Mobile: +420 603 728 936

E-mail:

Reference